Simulated Moving Bed (SMB) Systems

The basic principle of operation

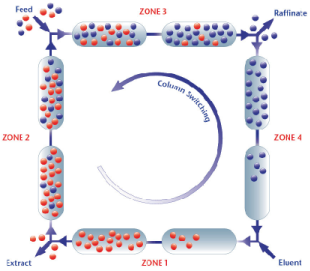

With normal chromatography, the mobile phase (the eluent) flows down the static, stationary phase (the column bed). However, it has been recognized for many years that it would be more efficient if the stationary phase could also move, in a counter-current to the mobile phase. But having a moving column bed is not practical, so to get around this a “simulated” moving bed system was developed which simulates the conditions of a moving bed through a circulating flow of feed, extract, eluent, and raffinate (the raffinate being what is left after the extract has been removed).

The bulk of the eluent is continuously circulated in the system, making it necessary to replace only that small amount which is removed in the extract and raffinate. This enables savings of up to 90% of the eluent in comparison to a batch process. Also, due to the simulated counter-current, the stationary phase is significantly better utilized with the SMB technique as compared to the batch process technique. The number of theoretical plates might be also less important, making it possible to use cost-effective larger particle sizes for the stationary phases.

Typically, the SMB process is used for mixtures of two components, like chiral separations or mixtures with a “leading” or a “trailing” key product peak in the chromatogram. But it is possible that each partial fraction can be separated into a further fraction by repeated use of the SMB process – down to binary substance mixtures.

The KNAUER AZURA® SMB System Configuration

KNAUER has refined the SMB methodology further to produce a unique system that avoids the requirement for a large rotating multi-position valve but instead utilizes seven smaller valves that give the system greater efficiency and flexibility.

The AZURA® SMB system consists of four pumps and seven multi-position valves. The devices are arranged as follows:

- Three pumps (Extract, Raffinate, Eluent) are placed inside the SMB cycle.

- The feed pump is placed outside the SMB cycle.

- Four valves are placed at the pump outlets.

- Three valves are placed at the pump inlets. The feed pump inlet is not connected to a multiposition valve.

Due to this configuration, the SMB system can be used very flexibly for many different separation modes. In addition to the process stability, AZURA® SMB systems are outperforming every other SMB system on the market regarding material and configuration flexibility as well as a usable pressure range.

SMB System for Continuous Chromatography on Laboratory Scale

The AZURA Lab SMB System is optimized for the multicolumn separation of binary mixtures of small molecules on a gram scale. The SMB System A29101 is the standard stainless steel configuration of our AZURA Lab SMB. It consists of seven 8-multiposition valves and four AZURA P 4.1S included in four Assistants ASM 2.2L. The high pressure range as well as the flexibility of the multiposition valves make this system the perfect solution for SMB chromatography.

With our preconfigured Upgrade-Kits you can upgrade your SMB chromatography system very easily and build up the system you need.

System and process control: A29800 (one CORI-FLOW), A29801 (four CORI-FLOW)

Heating and column organization: A29903 (oven), A29901 (column holder ID 50), A29902 (for columns with 8, 16 or 20mm ID)

SMB Biocompatible System for Continuous Chromatography on Laboratory Scale

The Biocompatible laboratory scale SMB System is optimized for the multicolumn separation of binary mixtures of small or biomolecules on a scale. The SMB System A29100 is the standard configuration of our AZURA Lab SMB. It consists of seven 8-multiposition valves and four AZURA P 4.1S included in four Assistants ASM 2.2L. The high pressure range and the biocompatibility as well as the flexibility of the multiposition valves make this system the perfect solution for SMB chromatography.

With our pre-configured Upgrade-Kits, you can upgrade your SMB chromatography system very easily and build up the system you need.

For example with system and process control: A29800 (one CORI-FLOW), A29801 (four CORI-FLOW)

SMB Pilot System for Continuous Purification

The SMB pilot system is dedicated to the continuous production of APIs. The System allows the continuous separation of mixtures of substances and extraction into two fractions. High purities and simultaneous yields of up to 100% distinguish this process from conventional preparative LC methods.

The system features four preparative Pumps 2.1L and seven multi-position valves integrated into four AZURA Assistans ASM 2.2L.

Cannabis Producer: SMB Pilot System for continuous cannabinoid production

Extracting high-purity pharmaceutical active ingredients from natural products at high yields is a major challenge. This also applies to the cannabinoid sector. Simulated Moving Bed (SMB) chromatography, as a continuous LC method, sets the standard for productivity, purity, and yield.

The AZURA SMB pilot system Cannabis Producer is dedicated to the continuous production of cannabinoids from cannabis. The Cannabis Producer allows the continuous separation of mixtures of substances and extraction into two fractions. High purities and simultaneous yields of up to 100% distinguish this process from conventional preparative LC methods.